1. Characteristics: medium hardness, good fluidity, low temperature resistance

2. Purpose: production of travel shoes, casual shoes, men's and women's leather shoes, and cotton shoes

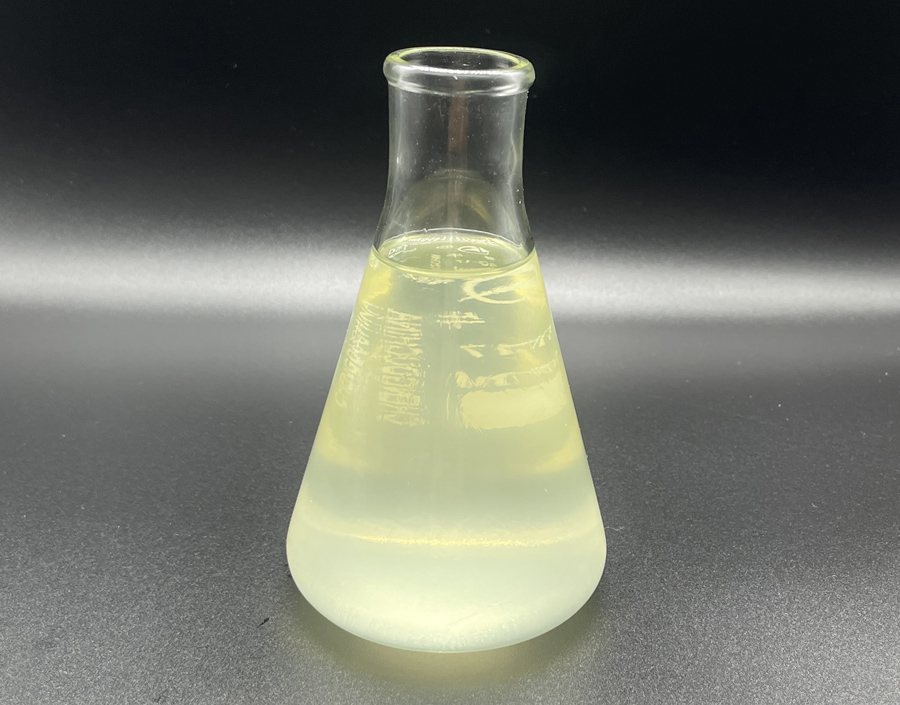

3. Characteristics of original solution

Product name | Exterior | Viscosity | density(g/cm3) | Storage stability (20 OCthe following) | Packaging |

SX-P-007 | liquid or waxy | 900~1300 | 1.16~1.19 | 6 months | 18Kg/bucket |

SX-I-003 | Transparent liquid without foreign matter | 200~500 | 1.18~1.20 | 3 months | 20Kg/bucket |

4. Catalysts and auxiliaries

The adding amount of SX-C-003 is 260±5g/18Kg, the adding amount of water is 75-90g/18Kg, and the adding amount of hardener SX-E-001 is 0-500 g/18Kg.

5. Molding conditions and physical property values

Reactivity | Technical Parameters | project | physical value | experiment method |

Reference scale P+C/I | 100/84~86 | Sole molding density (g/cm3) | 0.45~0.60 | GB/T6638—86 |

Operating temperature (oC) | 39~43/38~42 | hardness(A type) (C type) | 57~66 68~76 | GB/T3903—4 |

milky white time(s) | 6~9 | Tensile Strength (MPa) | 5.0~6.0 | GB/T6344 |

rise time (s) | 25~35 | Elongation(%) | 450~500 | GB/T6344 |

free bubble density(g/cm3) | 0.28~0.35 | Tear strength (kn/m) | 20~25 | GB/T10808 |

Metal mold temperature (oC) | 45~55 | Embrittlement temperature

| -25~-30 | GB/T15256 |

Demold time(min) | 5.0~7.0 | Folding endurance test (次,-23 oC) | 40,000 times without exception | GB/T3903.1 |

|

| NBS wear resistance (%) (data after pre-skin removal) | ≥30 | JCSS |

·The mixing ratio is based on the optimal mixing ratio value, which will vary with the type and amount of pigment additives added.

·Long-term storage of P-007 will cause the internal components to stratify, so stir evenly after heating and dissolving before use.·The density of free foam will vary depending on the season (temperature, humidity).

·The demoulding time will increase as the thickness of the molded product increases.

·The physical property data is obtained by testing a 6mm thick test piece.

·Folding endurance conditions: The bending angle is 50 degrees, the frequency is 230 times/min, and an average of 2 6mm incisions are pre-cut at the bending area, -23oc × 40,000 times.

·The above data is for reference only, and the specific data is subject to actual operation. If you need other physical property indicators, please contact our company.